About our Hardfacing Powders

Description

Diverse powders for use with plasma transfer arc welding (PTA) and laser cladding

Corrosion resistant buffer layer

High wear resistance while retaining ductility and repairability

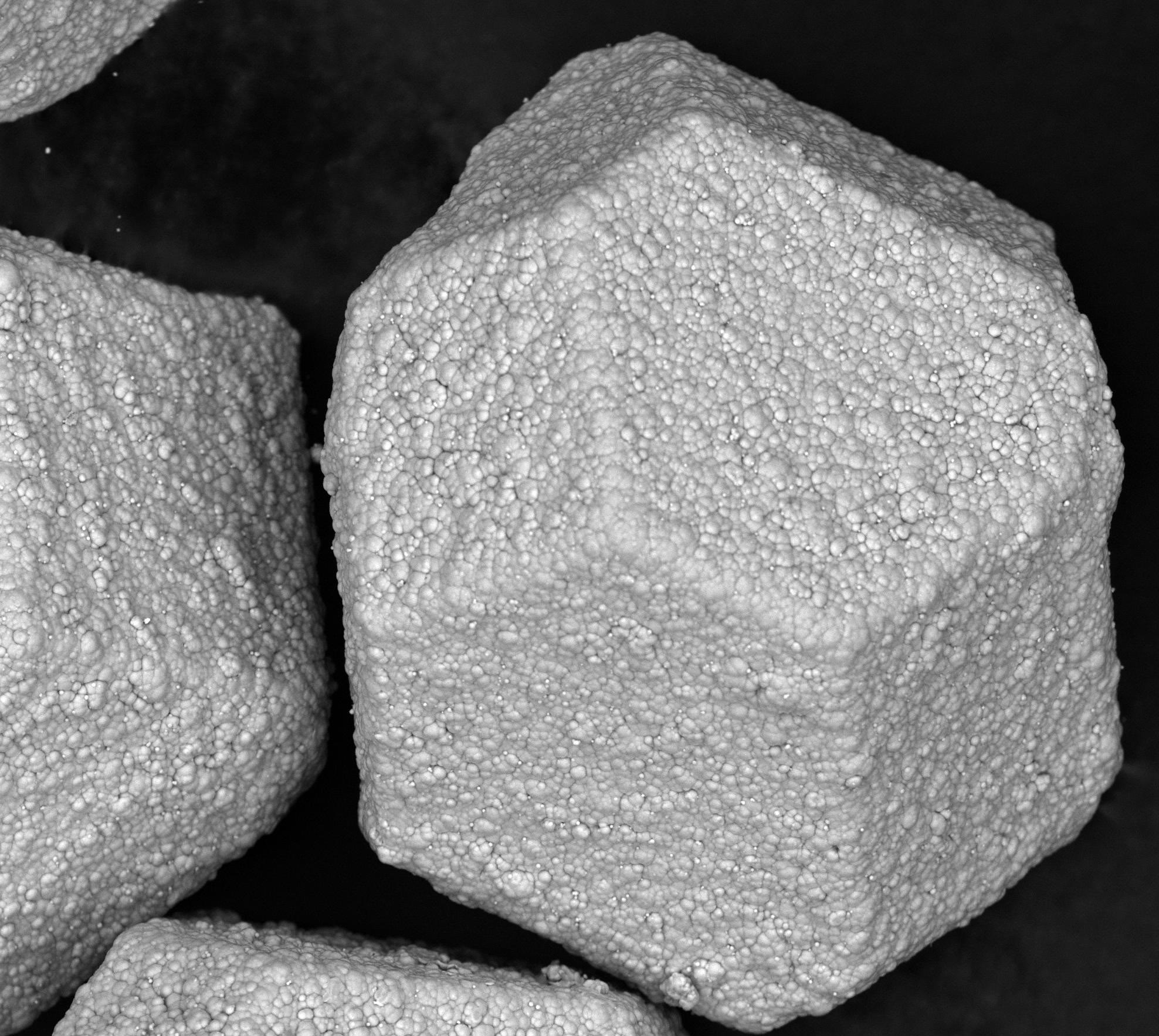

Diamond pellet and spherical fused tungsten carbide powders

Our Powder Types

FT-PO-Ni19-PL

Acts as a corrosion resistant buffer layer under tungsten carbide MMC composite exhibiting a high compatibility with tungsten carbide based hardfacing powders

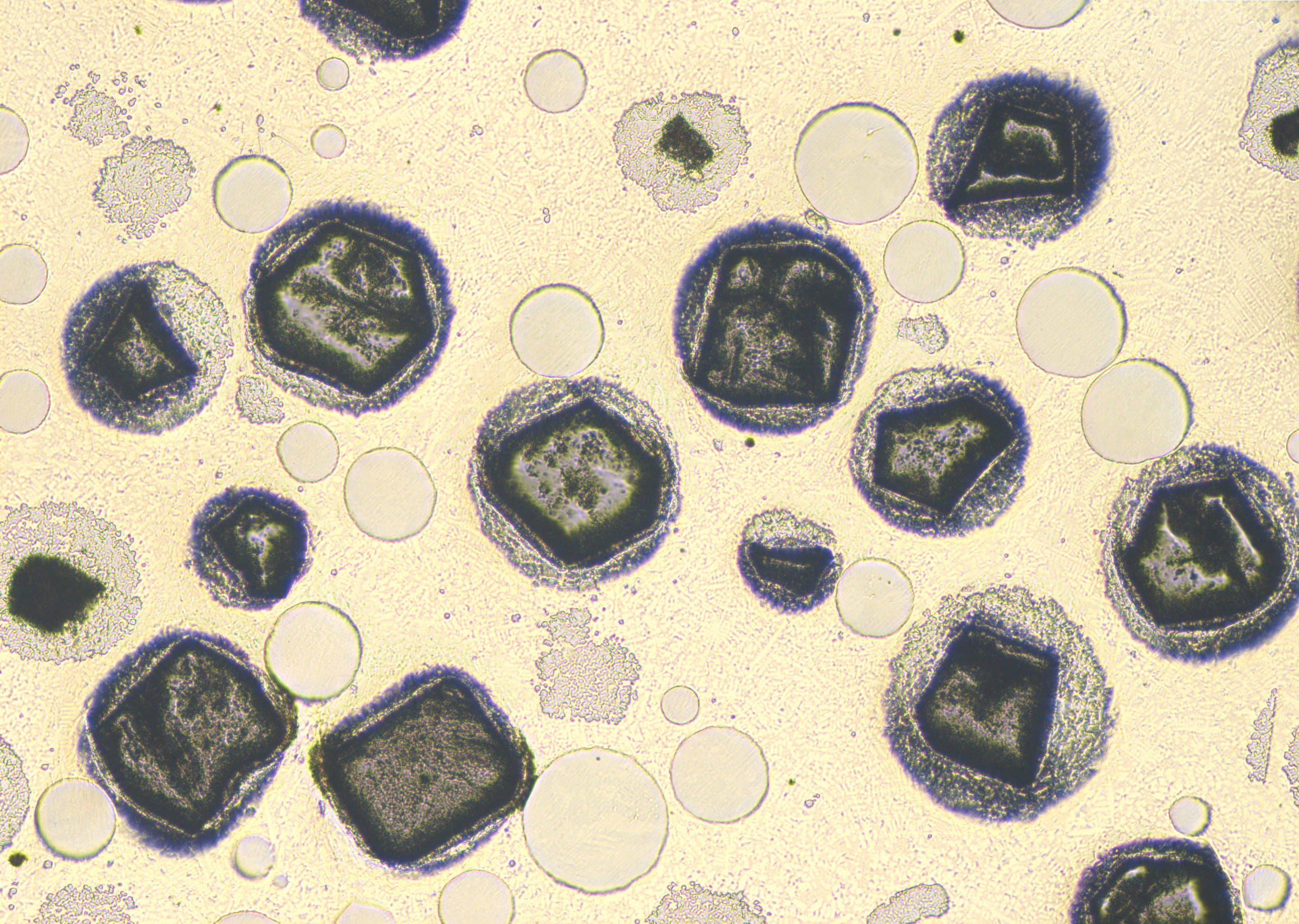

FT-PO-6035ST-PL

Composed of 60% spherical fused tungsten carbide in a NiCrBSi metal alloy exhibiting high wear resistance yet maintaining some ductility and repairability

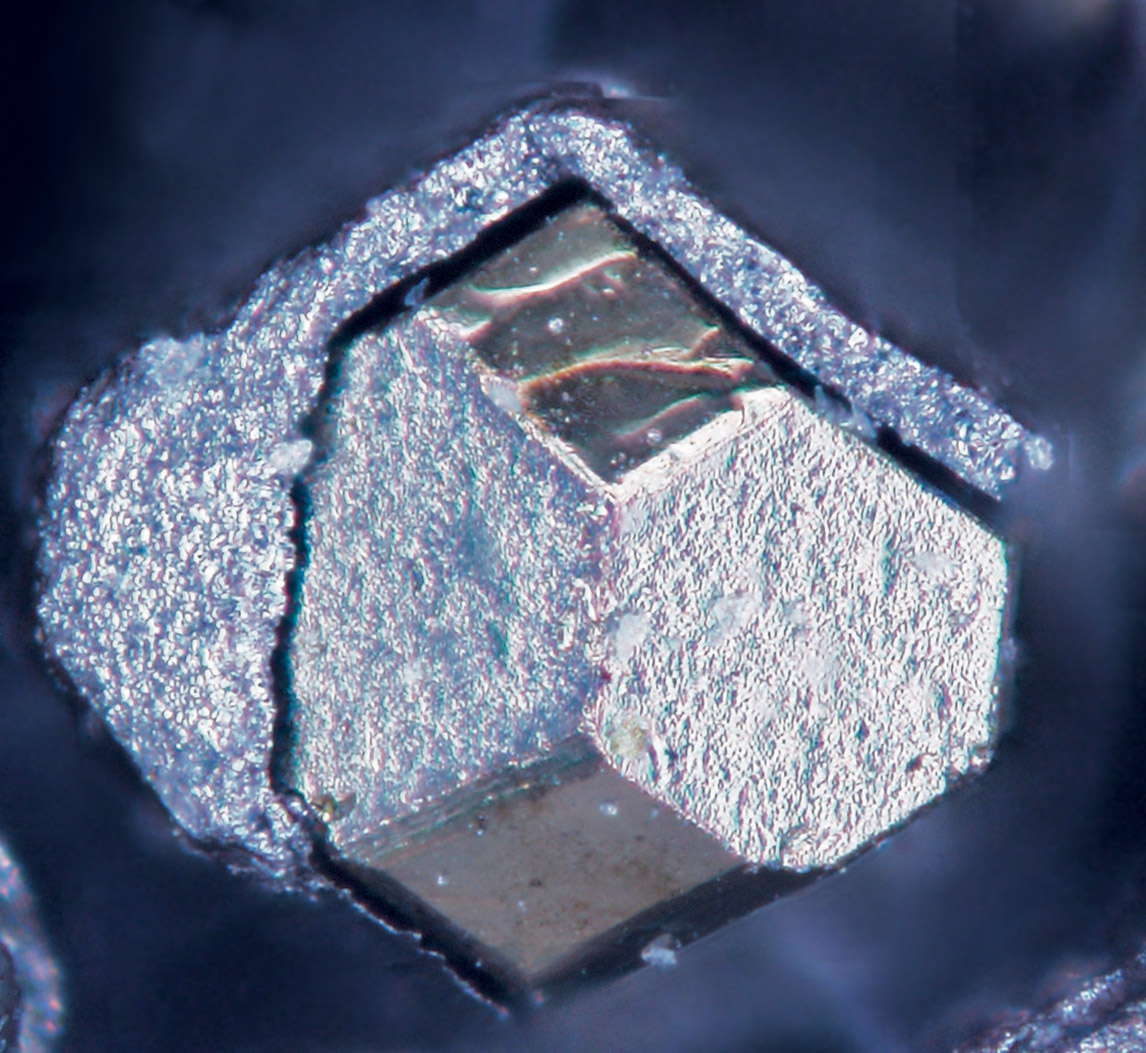

FT-PO-Dia20ST-PL

20% diamond pellets with a coating to protect and adhere during welding plus a high concentration of spherical fused tungsten carbide in a NiCrBSi metal alloy

FT-PO-Dia30ST-PL

30% diamond pellets and spherical fused tungsten carbide in a NiCrBSi metal alloy exhibiting high wear resistance yet maintaining some ductility and repairability

Application

Designed to repair and/or hard surface a wide range of ferritic and austenitic steel. Our powders have proven very effective at protecting components in the oil and gas industry such as downhole motor components (fixed bend housing, adjusting rings, stators...), ground engaging tools and industrial processing equipment including mixers, screws, pumps and more.

Diamond Cladding

Powder consumables for PTA and laser cladding processes where diamonds are used as a means to reinforce the coating for increased wear resistance